Welcome to the Sheron Frozen website!

Contact: Manager Wang

手 机:15904512533

电 话:13945013334

Address: No. 85-10 Haping Road, Xiangfang District, Harbin City

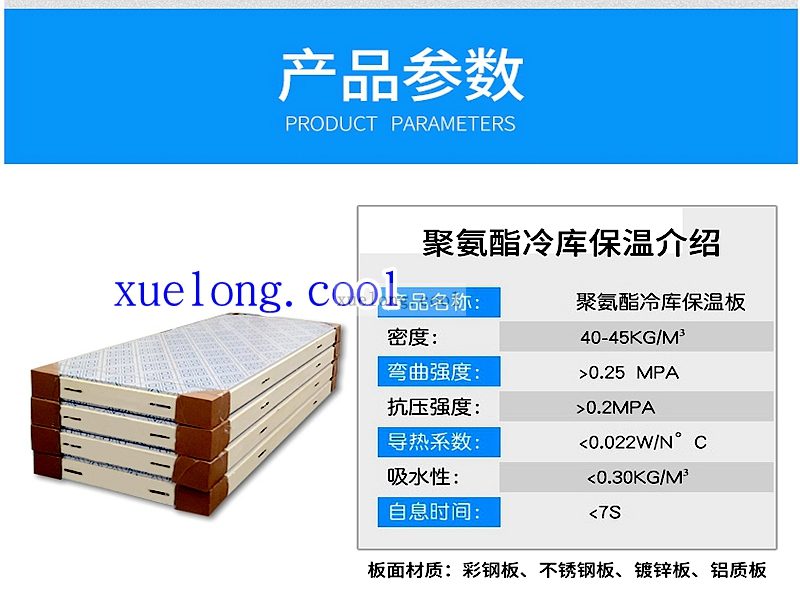

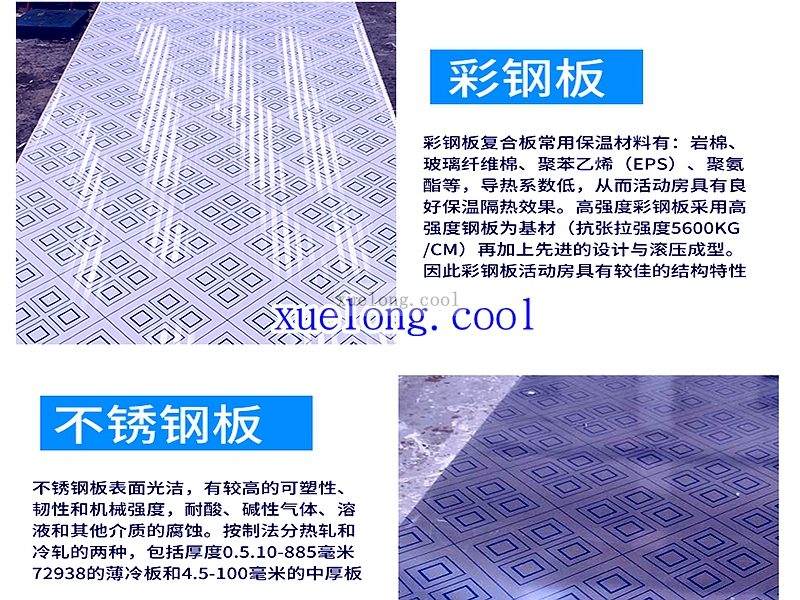

cold storage board using lightweight polyurethane foam as the inner core material of cold storage board, it is widely used in cold storage industry。The advantage of polyurethane is that it is very good at heat insulation,The exterior of the polyurethane cold storage board is made of colored steel and stainless steel plate components,The advantage of this is to prevent the spread of temperature due to the large temperature difference between inside and outside the cold storage plate,So that the cold storage more energy saving,It can hold heat like a refrigerator,Reduce electricity consumption and improve cooling efficiency。In the cold storage construction, the insulation material of the library body is polyurethane library board, the following is a brief description of the installation process and skills of polyurethane library board:

1. Contract customization and site inspection:

This link determines the most critical processes and skills for the construction quality of polyurethane cold storage: survey site size, design drawings, access channels。And good communication with the construction side, finally determine the construction size and plan。

2, the production plant construction warehouse board layout:

After the cold storage is completed in accordance with the contract, the manufacturer will issue the construction drawing of the storage board along with the storage board。Commonly known as assembly drawing。When unloading the warehouse board, strictly check the number and size of the warehouse board according to the factory construction drawing, and try to store it in accordance with the same specification and size, so as to facilitate the assembly according to the warehouse board number during construction。

3. Basic production and acceptance:

According to the different size of the library, the foundation of the library is divided into two categories: section steel field production and civil construction。Foundation production in strict accordance with the design scheme and drawings construction。The acceptance standard is levelness, which can be implemented according to the construction specifications of cold storage。The site can be measured and repaired according to the laser level。

Scan and consult wechat customer service

Scan and consult wechat customer service